Re-Engage

Returning-to-Work will be our theme in this edition of our report. We are going to remind our members about the tools/resources/rights they have related to health and safety when they re-engage at O.A.C. This has been one of the longest shutdowns we’ve ever had, with the most amount of retooling work completed since the plant was built in the early 1950’s. In our last issue (of the 707 Reporter) we talked about the I.R.S. (Internal Responsibility System). Now we would like to explain some resources that you have in the form of committees and provide you with some other return to work safety information. “News Flash” – the company has returned to the policy of mandatory safety glasses for everyone on any production floor.

Process Coach

The O.H.S.A. clearly states under Section 28 that you have a duty as a worker to report hazards to your supervisor. Both the employer and the supervisor (process coach) are legally responsible for your workplace safety. Therefore, your process coach must be made aware of your health a safety issues and we suggest that they be given time to address the issue, unless the issue is an immediately dangerous. If there does not seem to be any movement on your issue, then we strongly suggest that you get our office involved.

L.E.C. – Local Ergonomic Committee

The Local Ergonomic Committee is an effective tool you can use in resolving issues on your job. Its members include Union Ergo, Union Time Standards and the Joint Health & Safety Committee, along with all levels of management. At times, it could also include I.E. (Industrial Engineers), P.V.T. personnel (Plant Vehicle Team) Process Coaches, Team Leaders, and most importantly the base operator. This allows ergonomic issues to get resolved through collaboration of all parties involved.

Unifor Ergonomic Representation

Ergonomic safety topics encompass a broad range of issues related to the design of workplaces and tasks to minimize physical strain and promote well-being. Key areas include, lifting techniques, musculoskeletal disorders (MSDs), and ergonomic risk factors. Understanding these areas is crucial for preventing injuries and creating a comfortable, productive work environment. If you ever have any unaddressed ergo concerns on your job, feel free to reach out to our Union Ergonomic Representative – Kerry Kang. He is also the Co-Chair of the Local Ergonomic Committee. If you need to reach out to Kerry, his phone number is 905 – 845 – 2511 Ext. 2335 Email: ckang4@ford.com

Lift Assist – Unifor Time Standards Representation

Many jobs for the upcoming build of the Super Duty will have a Lift Assist (Hoist) required to do the job safely. These are put on the job when weight thresholds have exceeded the permissible limit. We absolutely stress to you to follow your O.I.S. (Operator Instruction Sheet). If you find that you do not have enough time to complete the job cycle, do not stop using the Lift Assist. Tell your Process Coach and get your Union Steward involved. If the issue continues you need to contact our Union Time Standards Committeeperson – Mike Longer. Mike is also part of the L.E.C. (Local Ergonomics Committee). If you ever find yourself with unanswered questions regarding the cycle time on your job, please contact him at 905 845 2511 Ext 3359 or email: mlonger@ford.com

Unifor Health and Safety Representatives

H & S representatives in the 1970s and 1980s use to be like safety cops: they punished people on infractions. This method has proven to be ineffective in creating a safe workplace. The philosophy these days concerning workplace on safety is to promote a strong safety culture! The J.H.S.C. promotes this culture and appreciates our members feedback of their concerns. This attitude with a strong focus and commitment to resolve issues, can help prevent any incidents or accidents in the plant. We strongly encourage you to report all unresolved health and safety concerns so that they can be addressed promptly. A non-reported safety concern before the end of the shift, indicates the workplace is 100 percent safe. Not reporting safety items gives a false positive of a safe workplace. The union Health and Safety office number is 905-845-2511 Extension 3362. Our email addresses are John Mullin – jmulli45@ford.com, Steve Gardiner – sgardi11@ford.com, Rob Kehoe – rkehoe@ford.com and Pat De Stephanis – pdesteph@ford.com Please contact us anytime with any questions or concerns. We will do our best to see you A.S.A.P.

P.M.H.V./Pedestrian Safety Committee

This committee is made up members of the JH&SC along with the support of the MP&L Area Manager, MP&L Team Managers, facilities/plant engineering, PMHV drivers and operators, and any other selected personnel as required, who should participate. The meeting cadence includes walking the plant floor and inspecting/surveying areas, viewing workflows, station layouts and equipment interface with pedestrian traffic.

W.W.S. / S.T.F.

We have written many articles on Walking Working Surfaces in the past. Slips, Trips, and Falls are a major cause of workplace injuries and preventing them requires a multi-faceted approach. Key safety strategy includes maintaining a clean and organized environment, using proper footwear, ensuring adequate lighting, and being mindful of potential hazards like wet floors or uneven surfaces. Many improvements in our facility have been recently completed, such as new parking lots, many new W.W.S. and new much brighter lighting. Our current strategy now is maintaining the flooring with zero W.W.S. issues. We would like to remind everyone if you ever have a slip, trip or fall or any type of workplace injury to:

• SEEK IMMEDIATE MEDICAL ATTENTION – from our plant’s First Aid Department, your Family Doctor, Clinic or Hospital.

• REPORT THE INCIDENT IMMEDIATELY – Report all workplace injuries/illnesses to your employer, no matter how minor they seem. Small issues can balloon quickly.

• SEEK UNION ASSISTANCE – Consult your W.S.I.B. Union Representative, Heather Longer 905 – 845 -2511 Ext. 3440

Email: hturnbu1@ford.com

• KEEP DOCUMENTATION – Obtain copies of all documents including employer’s, worker’s and doctor’s reports.

Emergency Evacuation

In our previous article we had mentioned that the plant has gone through a complete transformation. Upon returning, the company will be carrying out a series of evacuation drills. Emergency evacuation procedures involve a series of steps designed to safely remove people from a building or area during an emergency. Key actions include staying calm, following instructions from emergency personnel, identifying and using exit routes, and assembling at a designated muster point. When we all return to the plant, make sure you know exits / routes to get out safely. If you do not know, ask your Process Coach, if they do not know please call our office. If you need to report a plant emergency of any kind, please contact our Plant Protection at extension 3333.

Eye Wash Station

When you return to work, you may find yourself working with any chemicals such as solvents, cleaners, acids or bases. These should be identified in your O.I.S. (Operator Instruction Sheet) /J.S.A. (Job Safety Analysis). You should know the location of the nearest eyewash station before starting work. In an eye emergency, seconds matter. If you do happen to get any chemical or debris in your eyes, flush for 15 minutes and seek medical attention immediately after flushing. Please Note: These eyewash stations must be cleaned and inspected and tested regularly.

New Equipment – Pro Tagging

We wrote about “Pro-Tagging” in a previous issue but wanted to remind everyone on the company’s process for commissioning new equipment. Pro-Tagging is a color-coded system that processes new equipment in stages. In order for an operator to use new equipment it needs to be at the GREEN stage of the Pro Tag process. No equipment should be available for production unless it is at a GREEN level. If you ever have any questions regarding the status of new equipment, please do not hesitate to contact our office.

Anonymous Complaint

We have had some anonymous complaints put into the M.O.L. (Ministry of Labour) during this retooling period. The nature of the complaints seemed to indicate that the calls came from contractor’s employees. We have noticed that when contractors put complaints into the M.O.L., they rarely leave any contact information. The problem with putting in an anonymous complaint is that the M.O.L. cannot get back to you and share their investigation findings. We would prefer you go through our office, when you feel that you must contacting the M.O.L. We will not disclose your name to the company if that is your request. However, if you do feel that you must anonymously contact the M.O.L., you can ask them for your name to be withheld from the company. The 24-hour number Ministry of Labour is 1 877 202 0008

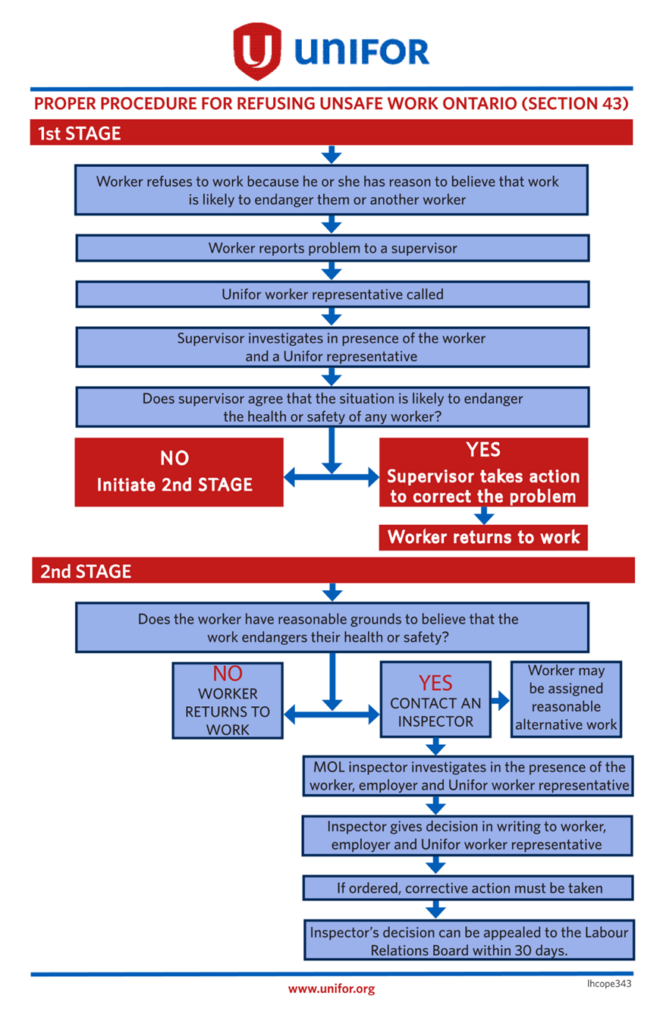

Work Refusal Procedures

The three main rights that workers have under the Occupational Health and Safety Act (O.H.S.A.) are the right to know about workplace hazards, the right to participate in health and safety discussions, and the right to refuse work that they believe is unsafe. When the I.R.S. has failed or you are faced with a dangerous situation, you may be forced to refuse unsafe work under the O.H.S.A. The following chart explains the proper steps to be taken.

Co-bots

“Co-bots,” or collaborative robots, are robots designed to work safely alongside humans in shared workspaces, rather than being isolated in dangerous environments. Unlike traditional robots, co-bots have advanced safety features, such as sensors, to detect human presence and halt operation or adjust speed if they get too close, preventing injury. Before implementing any co-bot, a thorough Risk Assessment must be completed with detailed J.S.A. (Job Safety Analysis) carried out by Company/J.H.S.C. to ensure the operator’s safety. These robots may have very little or no perimeter guards and people may be interacting or adjacent to them while they are working. You will also see yellow and black floor markings and “Authorized Personnel Only” signage that indicate robot safeguarded zones or collaborative zones. To enter these zones indicated by the markings and signs, you must be trained and authorized.

Asbestos Containing Material (A.C.M.) Removal at O.A.C.

Asbestos is banned, but the harm it can cause still lingers! We previously reported that abatement was being carried out on Asbestos Containing Material in the plant. This has continued during the retool period. Our goal was to effectively use the Hierarchy of Controls, through Elimination. When the retool is complete there may be very little left and any remaining A.C.M. will be at a very low risk if any to exposure.

O.B.C. – Ontario Building Code

Another tool we have been using to ensure everyone’s safety is the Ontario Building Code. The company needs to reassemble the plant and ensure no safety concerns are present. They also need to follow O.B.C. to meet local building standards which has safety intertwined.

Special Accolades

Over this retool period our office has worked very closely with our Skilled Trades Members. Special accolades go out to them; this was not an easy transition for any of us, especially the trades. Moving from an industrial environment into a construction-based environment is a totally different world. Our trades showed great ingenuity in problem solving and completing complex work. Some of the work completed was very precise and came with many controlled risks. We are proud to report that the work was completed, with the quality of the work, second to no one. Moving forward, our Skilled Trades are going to be such an asset: no one will know how to troubleshoot and repair something in the plant better than the people who helped build it!

In Closing

We are happy to see they have started populating the plant with our membership. Most civil work is now complete with tooling installation continuing in full swing. Emphasis will now move to commissioning all the new equipment. Upon returning the one dangerous safety habit we want to avoid are pedestrian “SHORTCUTS”. Please follow signage and floor markings, a 30 second walking time save is never worth a 3-month recovery from a broken ankle or possibly worse. We are going to once again show the company; that Oakville has the best workforce!

In Solidarity,

#3 Shift Representative

#3 Shift Representative